Cat® 773 (07)

Key Specs

- Nominal Payload Class (100%)

- 56 t

- Engine Model

- Cat® C27

- Top Speed - Loaded

- 67.6 km/h

Quiet, comfortable cab, intuitive controls and excellent visibility help operators work at their best all day long.

Elevated sprocket, rugged structures and proven systems give you long life and durability.

Differential steering and two-pump hydraulics give you the power and precision you need to maximize your productivity.

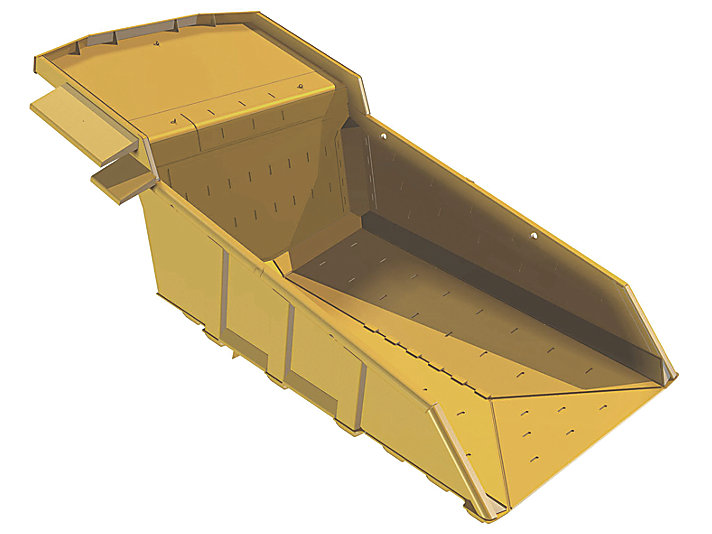

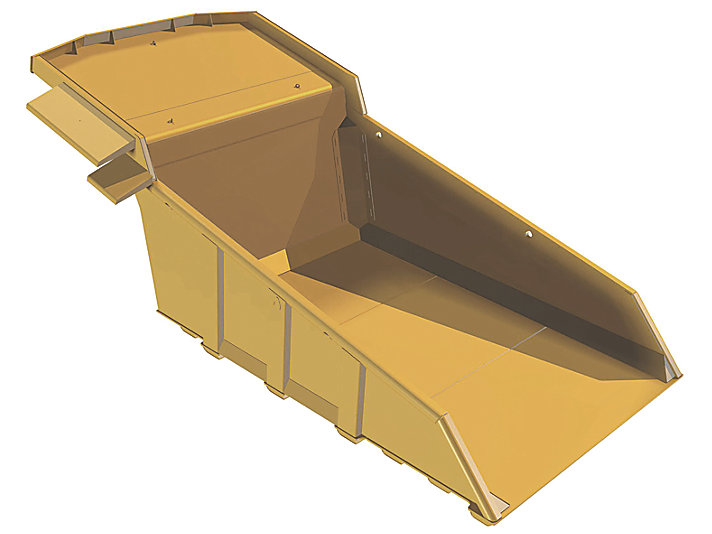

Caterpillar has body options to meet your material type and application needs. Cat truck bodies will last the life of the truck if properly configured, guarded, and maintained.

Both optional and standard features like those described here can increase the productivity of your operators:

An important differentiator for Cat trucks is their outstanding brake performance. The design principle is one of long-life and excellent performance in quarry, mine, and earthmoving applications.

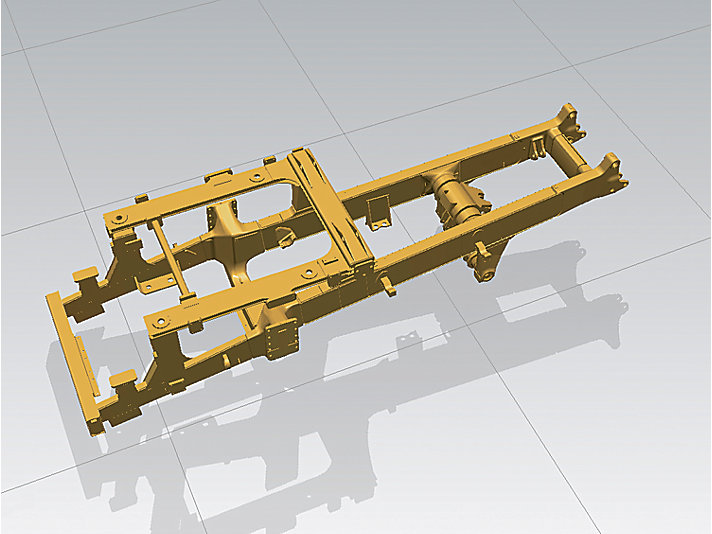

Cat trucks are known throughout the industry for reliable, long-life frames. Built for off-road maneuvering and haul road conditions, Caterpillar uses castings in high stress areas and box section construction to manage torsion-loading.

Caterpillar has body options to meet your material type and application needs. Cat truck bodies will last the life of the truck if properly configured, guarded, and maintained.

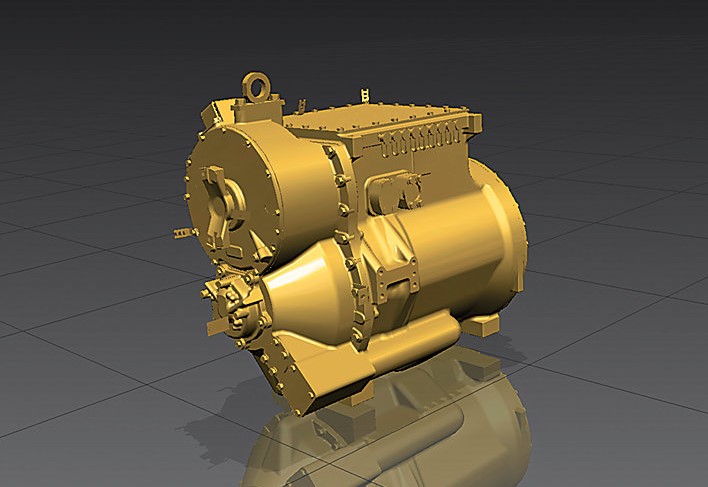

| Engine Model | Cat® C18 |

| Rated Engine Speed | 1700 r/min |

| Gross Power - SAE J1995 | 605 HP |

| Net Power - SAE J1349 | 550 HP |

| Net Power - ISO 9249 | 550 HP |

| Number of Cylinders | 6 |

| Bore | 5.7 in |

| Stroke | 7.2 in |

| Displacement | 1105 in³ |

| Net Torque - SAE J1349 | 2221 ft-lb |

| Engine Power - ISO 14396 | 598 HP |

| Target Gross Machine Operating Weight | 181000 lb |

| Chassis Weight | 59223 lb |

| Body Weight | 17306 lb |

| Target Gross Machine Weight | 181000 lb |

| Nominal Payload Class (100%) | 51.6 ton (US) |

| Top Speed - Loaded | 49.2 mile/h |

| Body Capacity - SAE 2:1 | 40.8 yd³ |

| Target Payload Capacity | 51.6 ton (US) |

| Not to Exceed Payload (120%) | 61.9 ton (US) |

| Maximum Payload Class (110%) | 56.7 ton (US) |

| Forward - 1 | 8 mile/h |

| Forward - 2 | 10.9 mile/h |

| Forward - 3 | 14.8 mile/h |

| Forward - 4 | 19.8 mile/h |

| Forward - 5 | 26.9 mile/h |

| Forward - 6 | 36.2 mile/h |

| Forward - 7 | 49.2 mile/h |

| Reverse | 10.4 mile/h |

| Differential Ratio | 2.74:1 |

| Planetary Ratio | 4.80:1 |

| Total Reduction Ratio | 13.14:1 |

| Brake Surface - Front | 216 in² |

| Brake Surface - Rear | 7794 in² |

| Brake Standards | ISO 3450:1996 |

| Pump Flow - High Idle | 118 gal/min |

| Relief Valve Setting - Raise | 2750 psi |

| Relief Valve Setting - Lower | 500 psi |

| Body Raise Time - High Idle | 7.5 s |

| Body Lower Time - Float | 10 s |

| Body Power Down - High Idle | 10 s |

| Struck | 31.3 yd³ |

| Heaped 2:1 (SAE) | 40.8 yd³ |

| Struck | 31.3 yd³ |

| Heaped 2:1 (SAE) | 40.9 yd³ |

| Front Axle - Empty | 51.4 % |

| Front Axle - Loaded | 34.2 % |

| Rear Axle - Empty | 48.6 % |

| Rear Axle - Loaded | 65.8 % |

| Rear axle - Oscillation | 8.9 ° |

| Empty Loaded Cylinder Stroke Rear | 5.8 in |

| Empty Loaded Cylinder Stroke Front | 9.2 in |

| Fuel Tank | 140 gal (US) |

| Cooling System | 33 gal (US) |

| Differential - Final Drives | 47 gal (US) |

| Steering Tank | 14.5 gal (US) |

| Steering System - Including Tank | 23 gal (US) |

| Torque Converter - Transmission System | 17 gal (US) |

| DEF Tank | 6 gal (US) |

| Brake Hoist System | 60 gal (US) |

| Crankcase | 17 gal (US) |

| Brake/Hoist Hydraulic Tank | 38 gal (US) |

| Standard Tire | 21.00R33 (E4) |

| ROPS Standards | ROPS (Rollover Protective Structure) for cab offered by Caterpillar meets ISO 3471:2008 ROPS criteria. |

| FOPS Standards | FOPS (Falling Objects Protective Structure) meets ISO 3449:2005 Level II FOPS criteria. |

| Sound Standards (1) | Hearing protection may be needed when operating with open operator station & cab for extended periods or in noisy environment. |

| Sound Standards (3) | Operator Equivalent Sound Pressure Level (Leq) is 74 dB(A) when ISO 6396:2008 is used to measure the value for an enclosed cab. |

| Sound Standards (2) | Exterior sound pressure power level for standard machine measured according to tests specified in ISO 6395:2008 is 115 dB(A). |

| Turning Diameter - Front | 57.7 ft |

| Steering Standards | ISO 5010:2007 |

| Steer Angle | 31 ° |

| Turning Circle - Clearance Diameter | 66.6 ft |

| Inside Body Depth - Maximum | 5.7 ft |

| Height - Top of ROPS | 12.8 ft |

| Overall Body Length | 26.8 ft |

| Inside Body Length | 19 ft |

| Overall Length | 28.9 ft |

| Wheel Base | 13 ft |

| Rear Axle - Tail | 9.5 ft |

| Ground Clearance | 1.6 ft |

| Dump Clearance | 1.5 ft |

| Loading Height - Empty | 11.6 ft |

| Overall Height - Body Raised | 27.1 ft |

| Operating Width | 15.7 ft |

| Centerline Front Tire Width | 10.4 ft |

| Engine Guard Clearance | 2 ft |

| Outside Body Width | 12.9 ft |

| Inside Body Width | 11.9 ft |

| Front Canopy Height | 13.7 ft |

| Rear Axle - Clearance | 1.9 ft |

| Centerline of Rear Dual Tire Width | 8.7 ft |

| Overall Tire Width | 12.9 ft |

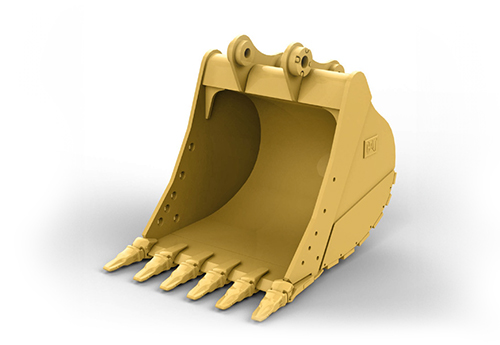

Cat buckets and Cat Ground Engaging Tools (GET) are designed and matched to the machine to ensure optimal performance and fuel efficiency.

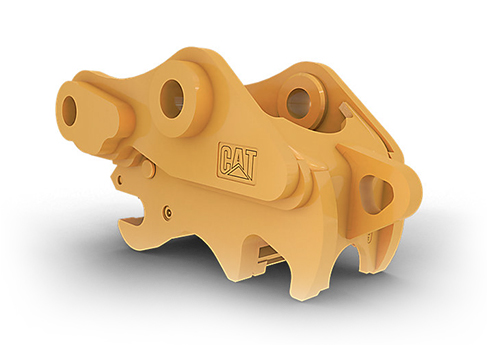

Center-Lock is a pin grabber coupler and features a patent-pending locking system. A highly visible secondary lock clearly shows the operator when the coupler is engaged or disengaged from the bucket or work tool..

Cat® Hammers make short work of your demolition, construction, and quarry needs. Combine the simple, lightweight design of the GC Hammer series with the reliability, durability, and value you expect from Cat products. The result is a low cost per hour solution providing the consistent power and performance you need.

Constructed from high-strength steels and built to last, Cat rippers endure in the toughest conditions. The box-section structure is reinforced for maximum rigidity, transmitting the full machine power to the material being ripped. Rippers feature a replaceable wear tip, and most models also come equipped with a replaceable shank protector.

Cat grapples make Cat excavators the ideal machine for handling loose material, sorting trash, and demolition site cleanup. An array of styles and sizes is available to match excavators to the task at hand.

Multi-processors do the work of many types of demolition tools by use of interchangeable jaw sets. Changing jaws allows a single unit to crush, pulverize, and perform a variety of specialized tasks such as cutting steel rebar and tanks.

Cat shears are designed to take full advantage of the hydraulic flows and pressures produced by Cat excavators – all to enhance productivity without compromising safety or causing premature wear of the shear or carrier.

Mechanical pulverizers are cost-effective tools for recycling demolished concrete debris. The bucket cylinder on the excavator powers the pulverizer, eliminating the need for a dedicated cylinder, associated hydraulics, and additional installation cost.

Cat compactors make job site compaction quick, efficient, and cost effective.

The hydraulic concrete crusher is well suited for demolition in residential areas. The tool combines several demolition operations in one piece of equipment: