Request A Quote

EFFICIENCY REIMAGINED NEXT GENERATION CAT® EXCAVATORS

CAT® 321- High Performance, Low Cost of Ownership

REDEFINING THE FUTURE

The new Next Generation Cat® 321, 322 and 324 hydraulic excavators are here, offering value and reliability you can count on. All models feature advanced Cat technology and shared Cat parts to simplify maintenance and reduce downtime. The 321 offers high torque and smooth, precise performance, helping to increase productivity with greater fuel efficiency. The 322 delivers improved acceleration and deep digging for high-volume production. And the 324 brings heavy-duty strength and precise control for grading, trenching and lifting applications. To explore the 321, 322 and 324 hydraulic excavators, talk to your local Cat dealer today.

Delivering Excellent Fuel Efficiency

- The Cat C3.6 engine and electrohydraulic system work in sync to help you move plenty of material while using less fuel.

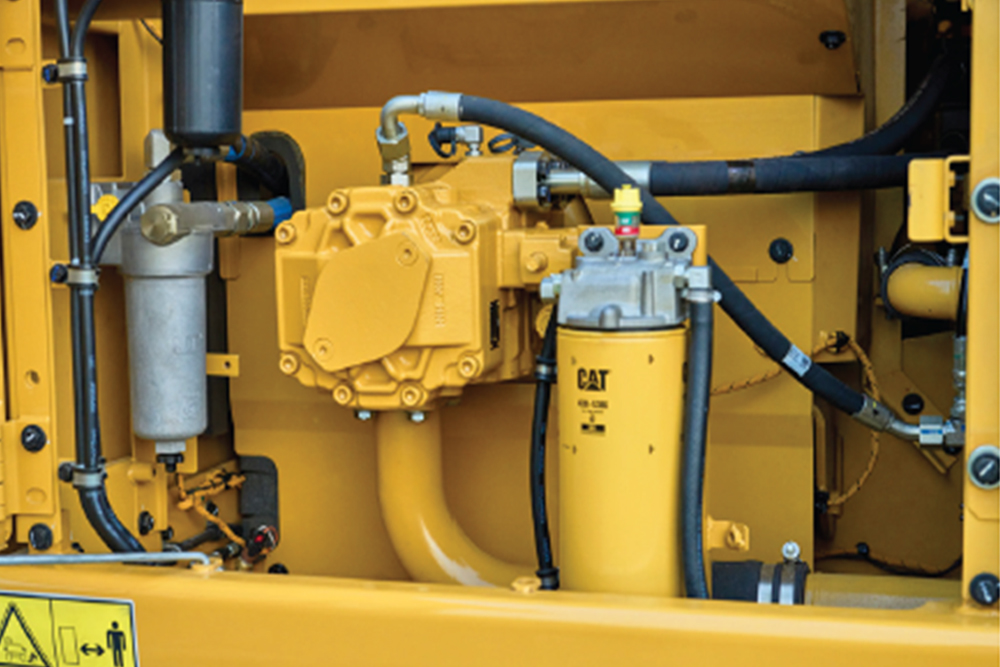

- Electro-hydraulic (EH) system eliminates the need for pilot lines and filter for improved response and enhanced savings.

- Intelligent Engine Control Module (ECM) ensures smooth, precise operation in every pass.

- Save fuel with Automatic Engine Control (AEC). It reduces engine speed when the machine is not under load to minimize fuel consumption.

- Robust and easy-to-maintain fuel system filtration reduces risk of failure from contaminated fuel.

- Boom and Stick regeneration circuits reduce fuel consumption while improving cycle times.

- Protect hydraulic components in cold weather. The auto warm-up feature speeds hydraulic oil warming in cooler temperatures.

Built to Last

- Reinforced Cat structures extend machine life in harsh working conditions.

- Reliable and durable and built on classic, proven components.

- Robotically welded booms and sticks ensure structural integrity.

- Track guards and steep-angle design shed debris, reducing wear.

- Choose between two robust undercarriage options: standard 4.1 m (13'5") or medium 4.25 m (13'11"), both built to withstand demanding conditions.

- The single plane cooling package design reduces air resistance compared to the traditional two-plane design for better cooling performance and enhanced machine productivity.

- Sloped track frame helps prevent mud and debris from accumulating in the track area.

- High swing speed and proven Cat components keep you working longer.

Low Maintenance, More Uptime

- Shared components simplify maintenance and improve parts availability.

- Scheduled Oil Sampling (S·O·SSM) ports are on ground level, simplifying maintenance and allowing for quick, easy extraction of samples for fluid analysis.

- Extended and synchronized service intervals save on maintenance costs.

- Extended first engine oil change interval (500 hours), and maintenance-free batteries.

- Maximize uptime and extended service intervals, thanks to advanced hydraulic oil filter design and no pilot and case drain filters.

- Proven, high-efficiency radial seal engine air filter behind the cab. The machine constantly monitors the engine air filter and will notifyyou, via the monitor, when service is required.

- The latest air intake filter with pre-cleaner has double the dust holding capacity of the previous air intake filter.

Safety First, Always

- The latest cab provides excellent visibility from the operator’s seat. In addition, two standard mirrors help keep you aware of your surroundings.

- Optional rearview camera enhances visibility behind the machine.

- Optional front windshield guard helps protect the windshield from potential damage caused by rocks, flying debris, and other road materials.

- Heavy-duty base frame and reinforced “X” car body conform to ISO 15818:2017 lifting and tie-down requirements.

- Handrails and hand hold with a step on the undercarriage for easy access to the engine bay area. The handrails conform to ISO 2867:2011 requirements for added safety.

- Anti-skid plating with countersunk bolts reduces the potential for slippage and trip hazards.

Simple to Operate

- Start the engine with a push button.

- The in-cab high-resolution 203 mm (8 in) touchscreen monitor is easy to use, intuitive, and user-friendly.

- Continuously improved user interface allows for intuitive navigation, minimizing performance interruption with the easy-to-use touchscreen menu.

- The machine’s electrohydraulic system allows accurate bucket control for maximum precision.

- Optimized low-effort joystick controls reduce operator fatigue.

- Customize joystick patterns and preferences; the machine remembers each operator's settings.

- Auto hammer stop protects tools from overheating and wear.

Comfort That Keeps You Going

- Ergonomically designed seat to improve operator’s comfort.

- Sound suppression, seals, and viscous cab mounts decrease noise and vibration for a quieter work environment.

- Excellent work site visibility from the cab enhances productivity and safety.

- Adjustable seat with three suspension levels and ergonomic design.

- Climate control, Bluetooth® connectivity, USB ports, and an intuitive interface enhance comfort.

- Easy to access radio controls, engine throttle, wiper controls and Bluetooth phone pairing for operator convenience.

- Bright seatbelts and a wide cab entry improve safety and usability.

Smart Fleet Management

- VisionLinkTM wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business. Gain valuable insight into how your machine or fleet is performing. Access data anywhere—desktop, tablet, or mobile device.

- Available CVA (Customer Value Agreements) and EPP (Extended Protection Plans) help maximize uptime and reduce risk.

- Cat dealers are second to none. From machine selection and purchase to maintenance support, operator training and rebuilds, Cat dealers have the experience and capabilities to help keep you up and running at peak performance.

CAT® 324- Heavy-Duty Muscle for High-Volume Jobs

REDEFINING THE FUTURE

The new Next Generation Cat® 321, 322 and 324 hydraulic excavators are here, offering value and reliability you can count on. All models feature advanced Cat technology and shared Cat parts to simplify maintenance and reduce downtime. The 321 offers high torque and smooth, precise performance, helping to increase productivity with greater fuel efficiency. The 322 delivers improved acceleration and deep digging for high-volume production. And the 324 brings heavy-duty strength and precise control for grading, trenching and lifting applications. To explore the 321, 322 and 324 hydraulic excavators, talk to your local Cat dealer today.

High Performance, Fuel Efficient

- The turbocharged Cat C7.1 engine with Cat filters offers high power density with a combination of proven fuel and air systems.

- Eco mode reduces fuel consumption with no loss in lifting or digging forces.

- Equipped with electrohydraulic control valve, pump and Engine Control Module (ECM) for better controllability and high fuel efficiency.

- The ECM ensures smooth, precise operation in every pass.

- Balance power and fuel efficiency using the Positive Flow Control (PVC) electro-hydraulic system.

- Use automatic engine speed control (AEC) during no-load or lightload conditions to automatically reduce engine speed to minimize fuel consumption.

- Electronic tandem hydraulic pumps deliver more efficiency with less internal friction losses and superior design.

- Boom and stick regeneration circuits reduce fuel consumption while improving cycle times.

Built for Long Term Production

- Move more material with a large 1.4 m³ (1.83 yd³) General-Duty bucket for earthmoving.

- Be more productive with a size class exclusive 1.3 m³ (1.70 yd³) Severe-Duty bucket for quarry to handle rock, gravel and abrasive material.

- Engineered for consistent reliability across long shifts and rough terrain.

- Cooling system capability of up to 48º C (118º F) for good performance in harsh environments.

- Standard high-ambient temperature capability of 52° C (126° F) and cold start capability of –10° C (14° F).

- The single plane cooling package design reduces air resistance compared to the traditional two-plane design for better cooling performance and enhanced machine productivity.

- Traverse the jobsite on the Grease Lubricated Track (GLT) 4.45 m (14'7") Long undercarriage.

- Work up to 3000 m (9,840 ft) above sea level without de-rating.

Reliability You Can Count On

- Caterpillar design and manufacturing techniques assure outstanding service life.

- Reliable and durable and built on classic, proven components.

- Robotically welded booms and sticks ensure structural integrity.

- Dig and lift from a stable platform created by the 4550 kg (10,030 lb) heavy-duty counterweight and heavy-duty eight-roller undercarriage.

- Long 4.45 m (14'7") undercarriage delivers excellent stability and ground contact, supporting versatile, high-productivity performance across a range of demanding applications.

- Hydraulic lines protected inside the frame reduce damage risk.

- Grease sealed between track pins and bushings reduces travel noise and prevents debris from entering to increase undercarriage life.

- Reinforced structures and upgraded undercarriages improve stability and durability.

Reduce Your Maintenance Time and Costs

- The 324 features a safe, convenient work platform for routine service and maintenance. Anti-skid plating with countersunk bolts reduces slip and trip hazards, while integrated grips on key areas ensure easy access to the platform and operator station.

- Shared components simplify maintenance and improve parts availability.

- Scheduled Oil Sampling (S·O·SSM) ports are on ground level, simplifying maintenance and allowing for quick, easy extraction of samples for fluid analysis.

- Extended and synchronized service intervals save on maintenance costs.

- Extended first engine oil change interval (500 hours), and maintenance-free batteries.

- Filters, such as fuel, engine air, and oil filters, are grouped together for easy access and preventative maintenance.

Safely Home Every Day

- The latest cab provides excellent visibility from the operator’s seat. In addition, two standard mirrors help keep you aware of your surroundings.

- Optional front windshield guard helps protect the windshield from potential damage caused by rocks, flying debris, and other road materials.

- Optional rearview camera enhances visibility behind the machine.

- Heavy-duty base frame and reinforced “X” car body meets ISO 15818:2017 lifting and tie-down requirements.

- The optional Rollover Protective Structure (ROPS) cab meets ISO 12117-2:2008 requirements.

- Handrails and hand hold are provided for easy access. The handrails meet ISO 2867:2011 requirements for added safety.

- Ground-level access for daily checks improves safety and saves time.

Simple to Operate

- Start the engine with a push button.

- The in-cab high-resolution 203 mm (8 in) touchscreen monitor is easy to use, intuitive, and user-friendly.

- Continuously improved user interface allows for intuitive navigation, minimizing performance interruption with the easy-to-use touchscreen menu.

- The machine’s electrohydraulic system allows accurate bucket control for maximum precision.

- Optimized low-effort joystick controls reduce operator fatigue.

- Customize joystick patterns and preferences; the machine remembers each operator's settings.

- Auto hammer stop protects tools from overheating and wear.

Smart Fleet Management

- VisionLinkTM wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business. Gain valuable insight into how your machine or fleet is performing. Access data anywhere – desktop, tablet, or mobile device.

- Available CVA (Customer Value Agreements) and EPP (Extended Protection Plans) help maximize uptime and reduce risk.

- Cat dealers are second to none. From machine selection and purchase to maintenance support, operator training and rebuilds, Cat dealers have the experience and capabilities to help keep you up and running at peak performance.

CAT® 322- Efficiency That Pays You Back

REDEFINING THE FUTURE

The new Next Generation Cat® 321, 322 and 324 hydraulic excavators are here, offering value and reliability you can count on. All models feature advanced Cat technology and shared Cat parts to simplify maintenance and reduce downtime. The 321 offers high torque and smooth, precise performance, helping to increase productivity with greater fuel efficiency. The 322 delivers improved acceleration and deep digging for high-volume production. And the 324 brings heavy-duty strength and precise control for grading, trenching and lifting applications. To explore the 321, 322 and 324 hydraulic excavators, talk to your local Cat dealer today.

Designed for Uptime

- Caterpillar design and manufacturing techniques assure outstanding service life

- Thorough component design and machine validation processes result in unmatched reliability and uptime.

- Reinforced front structures help extend machine life in demanding terrain.

- Robotically welded booms and sticks ensure structural integrity.

- Dig and lift from a stable platform created by the 4000 kg (8,820 lb) heavy-duty counterweight and eight-roller undercarriage.

- Hydraulic lines protected inside the frame reduce damage risk.

- Auto warm up speeds up hydraulic oil warming in cold temperatures and helps prolong the life of components.

- The latest single-plane cooling package has better air flow, helping to reduce fan speed and save fuel in cooler conditions and lighter applications.

Low Fuel Consumption

- The Turbocharged Cat C3.6 engine and electrohydraulic system work in sync to help you move loads of material without burning excessive fuel.

- Eco mode reduces fuel consumption with no loss in lifting or digging forces.

- Equipped with electrohydraulic control valve, pump and Engine Control Module (ECM) for better controllability and high fuel efficiency.

- The ECM ensures smooth, precise operation in every pass.

- Balance power and fuel efficiency using the Positive Flow Control (PVC) electrohydraulic system.

- Electronic tandem hydraulic pumps deliver more efficiency with less internal friction losses and superior design.

- Boom and stick regeneration circuits reduce fuel consumption while improving cycle times.

High Productivity

- Choose from a 1.2 m³ (1.57 yd³) General Duty bucket or a 1.14 m³ (1.49 yd³) General Duty bucket for earthmoving tasks. For quarry applications, select the 1.1 m³ (1.44 yd³) Severe Duty bucket, engineered to handle rock, gravel, and abrasive materials with ease.

- Choose between two robust undercarriage options: Medium 4.25 m (13'11") or Long 4.45 m (14'7"), both built to withstand demanding conditions.

- Increased swing torque compared to the 320D3 delivers seamless operations while grading, truck loading and trenching.

- Traverse the jobsite on the Grease Lubricated Track (GLT) undercarriage. Undercarriage rollers are rebuildable and sealed to prevent dirt and debris from causing internal wear.

- Work up to 3000 m (9,840 ft) above sea level without de-rating.

Save on Service and Maintenance

- The 322 features a safe, convenient work platform for routine service and maintenance. Anti-skid plating with countersunk bolts reduces slip and trip hazards, while integrated grips on key areas ensure easy access to the platform and operator station.

- Shared components simplify maintenance and improve parts availability.

- Scheduled Oil Sampling (S·O·SSM) ports are on ground level, simplifying maintenance and allowing for quick, easy extraction of samples for fluid analysis.

- Extended and synchronized service intervals save on maintenance costs.

- Extended first engine oil change interval (500 hours), and maintenance-free batteries.

- Filters, such as fuel, engine air, and oil filters, are grouped together for easy access and preventative maintenance.

Safely Home Every Day

- The latest cab provides excellent visibility from the operator’s seat. In addition, two standard mirrors help keep you aware of your surroundings.

- Optional front windshield guard helps protect the windshield from potential damage caused by flying debris, and other road materials.

- Optional rearview camera enhances visibility behind the machine.

- Heavy-duty base frame and reinforced “X” car body conform to ISO 15818:2017 lifting and tie-down requirements.

- The optional Rollover Protective Structure (ROPS) cab conforms to ISO 12117-2:2008 requirements.

- Handrails and hand hold with a step on the undercarriage for easy access to the engine bay area. The handrails conform to ISO 2867:2011 requirements for added safety.

- Anti-skid plating with countersunk bolts reduces the potential for slippage and trip hazards.

Simple to Operate

- Start the engine with a push button.

- The in-cab high-resolution 203 mm (8 in) touchscreen monitor is easy to use, intuitive, and user-friendly.

- Continuously improved user interface allows for intuitive navigation, minimizing performance interruption with the easy-to-use touchscreen menu.

- The machine’s electrohydraulic system allows accurate bucket control for maximum precision.

- Optimized low-effort joystick controls reduce operator fatigue.

- Customize joystick patterns and preferences; the machine remembers each operator's settings.

- Auto hammer stop protects tools from overheating and wear.

Smart Fleet Management

- VisionLink™ wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business. Gain valuable insight into how your machine or fleet is performing. Access data anywhere—desktop, tablet, or mobile device.

- Available CVA (Customer Value Agreements) and EPP (Extended Protection Plans) help maximize uptime and reduce risk.

- Cat dealers are second to none. From machine selection and purchase to maintenance support, operator training and rebuilds, Cat dealers have the experience and capabilities to help keep you up and running at peak performance.