Cat® 120 GC

Key Specs

- Net Power - ISO 9249/SAE J1349

- 128 kW

- Operating Weight - Typically Equipped

- 14496 kg

- Blade Width

- 3.7 m

Power shift countershaft transmission matched to engine maximizes power to the ground.

Aggressive blade angles, optimized moldboard curvature and large throat clearance allows material to roll more freely along blade.

Optional AutoShift transmission maximizes productivity by automatically shifting the transmission at optimal shift points.

Cat C7 engine meets Bharat Stage III equivalent and China Nonroad Stage III emission standards, depending on emission standards of specific country.

Electronic Throttle Control helps improve productivity by optimizing HP and torque to match the power demands of the application.

Proportional Priority Pressure-Compensating (PPPC) provides load-sensing hydraulics with superior control, enhanced performance, and efficiency.

Sacrificial brass moldboard slide rail wear strips between blade mounting group and moldboard can be easily adjusted and replaced.

Utilizing rigorous component design and machine validation processes results in unmatched reliability, durability and high uptime.

Optional HVAC, defroster fan and sun shades keep you comfortable, while conveniently placed power ports keep additional communication devices charged and ready.

.jpg)

Optional Cat AccuGrade™ uses positioning and guidance technologies, machine sensors, and automatic blade control to help get to grade faster, easier, and more efficiently.

.jpg)

Standard circle drive slip clutch protects the drawbar, circle and moldboard from shock loads when the blade encounters an immovable object.

| Base Power (1st Gear) - Net | 171 HP |

| Engine Model | Cat C7 |

| Displacement | 439 in³ |

| Maximum Torque | 735 ft·lbf |

| Note (2) | Net power advertised is the power available at rated speed of 2,000 rpm, measured at the flywheel when engine is equipped with fan, air cleaner, muffler and alternator. |

| Bore | 4.1 in |

| Torque Rise | 46% |

| Note (3) | Maximum torque measured at 1,000 rpm in gears 4-8. |

| Stroke | 5 in |

| Speed at Rated Power | 2,000 rpm |

| Note (1) | Net power is tested per ISO 9249, SAE J1349, and EEC 80/1269 standards in effect at the time of manufacture. |

| Number of Cylinders | 6 6 |

| Derating Altitude | 10000 ft |

| High - Ambient Capability | 122 °F |

| High Ambient - Fan Speed - Maximum | 1,560 rpm |

| VHP Range - Net | 128-143 kW (171-191 hp) |

| Blade Width | 12 ft |

| Throat Clearance | 4.7 in |

| Arc Radius | 16.3 in |

| Cutting Edge Thickness | 0.6 in |

| End Bit - Thickness | 0.6 in |

| Moldboard - Height | 24 in |

| Moldboard - Thickness | 0.9 in |

| End Bit - Width | 6 in |

| Cutting Edge Width | 6 in |

| Maximum Shoulder Reach Outside of Tires - Left | 74.6 in |

| Moldboard Sideshift - Left | 20.2 in |

| Maximum Depth of Cut | 28.9 in |

| Blade Tip Range - Forward | 40° |

| Circle Centershift - Right | 28.7 in |

| Maximum Shoulder Reach Outside of Tires - Right | 77.9 in |

| Maximum Lift Above Ground | 18.9 in |

| Blade Tip Range - Backward | 5° |

| Moldboard Sideshift - Right | 26.1 in |

| Circle Centershift - Left | 29.6 in |

| Front Axle - Total Oscillation per Side | 32° |

| Front Axle - Wheel Lean - Left/Right | 18° |

| Circle - Outer Diameter | 60.2 in |

| Gross Vehicle Weight - Typically Equipped | 38076 lb |

| Gross Vehicle Weight - Base - Total | 32518 lb |

| Gross Vehicle Weight - Typically Equipped - Rear Axle | 27193 lb |

| Gross Vehicle Weight - Typically Equipped - Total | 38076 lb |

| Gross Vehicle Weight - Base - Front Axle | 9390 lb |

| Gross Vehicle Weight - Base - Rear Axle | 23128 lb |

| Gross Vehicle Weight - Typically Equipped - Front Axle | 10883 lb |

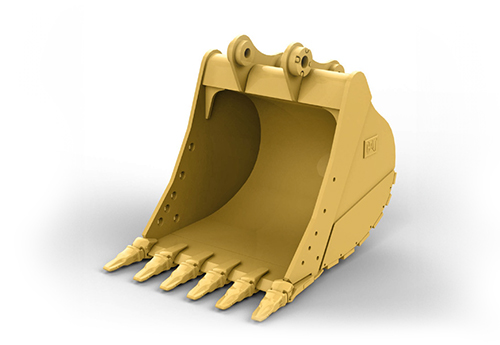

Cat buckets and Cat Ground Engaging Tools (GET) are designed and matched to the machine to ensure optimal performance and fuel efficiency.

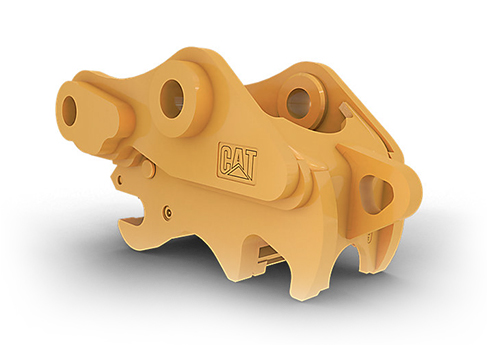

Center-Lock is a pin grabber coupler and features a patent-pending locking system. A highly visible secondary lock clearly shows the operator when the coupler is engaged or disengaged from the bucket or work tool..

Cat® Hammers make short work of your demolition, construction, and quarry needs. Combine the simple, lightweight design of the GC Hammer series with the reliability, durability, and value you expect from Cat products. The result is a low cost per hour solution providing the consistent power and performance you need.

Constructed from high-strength steels and built to last, Cat rippers endure in the toughest conditions. The box-section structure is reinforced for maximum rigidity, transmitting the full machine power to the material being ripped. Rippers feature a replaceable wear tip, and most models also come equipped with a replaceable shank protector.

Cat grapples make Cat excavators the ideal machine for handling loose material, sorting trash, and demolition site cleanup. An array of styles and sizes is available to match excavators to the task at hand.

Multi-processors do the work of many types of demolition tools by use of interchangeable jaw sets. Changing jaws allows a single unit to crush, pulverize, and perform a variety of specialized tasks such as cutting steel rebar and tanks.

Cat shears are designed to take full advantage of the hydraulic flows and pressures produced by Cat excavators – all to enhance productivity without compromising safety or causing premature wear of the shear or carrier.

Mechanical pulverizers are cost-effective tools for recycling demolished concrete debris. The bucket cylinder on the excavator powers the pulverizer, eliminating the need for a dedicated cylinder, associated hydraulics, and additional installation cost.

Cat compactors make job site compaction quick, efficient, and cost effective.

The hydraulic concrete crusher is well suited for demolition in residential areas. The tool combines several demolition operations in one piece of equipment: