Cat® 321

- Operating weight

- 19,300 kg

- Engine Power

- 100 kW / 136 hp

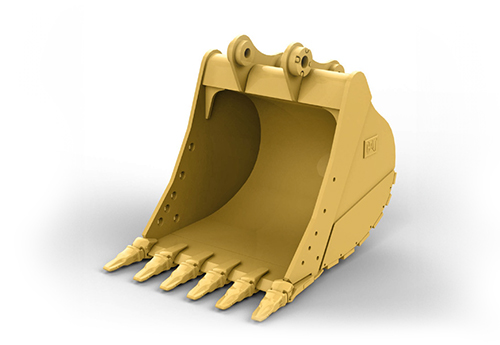

- Bucket Capacity

- GD 1.0

- Description

-

- Best in class fuel efficient machine.

- Powerful and reliable Cat C3.6 electronic engine

- Most efficient & reliable hydraulic system

- 3 Mode Operation - Power, Smart & Eco

- Robust structures for the toughest applications