Cat® 316 GC

- Operating Weight

- 14400 kg

- Engine Power

- 68.2 kW / 91 hp

- Bucket Capacity

- 076 HD / 0.8 GD

- Description

-

- The 316 GC offers best in class performance and Productivity with Low operating costs.

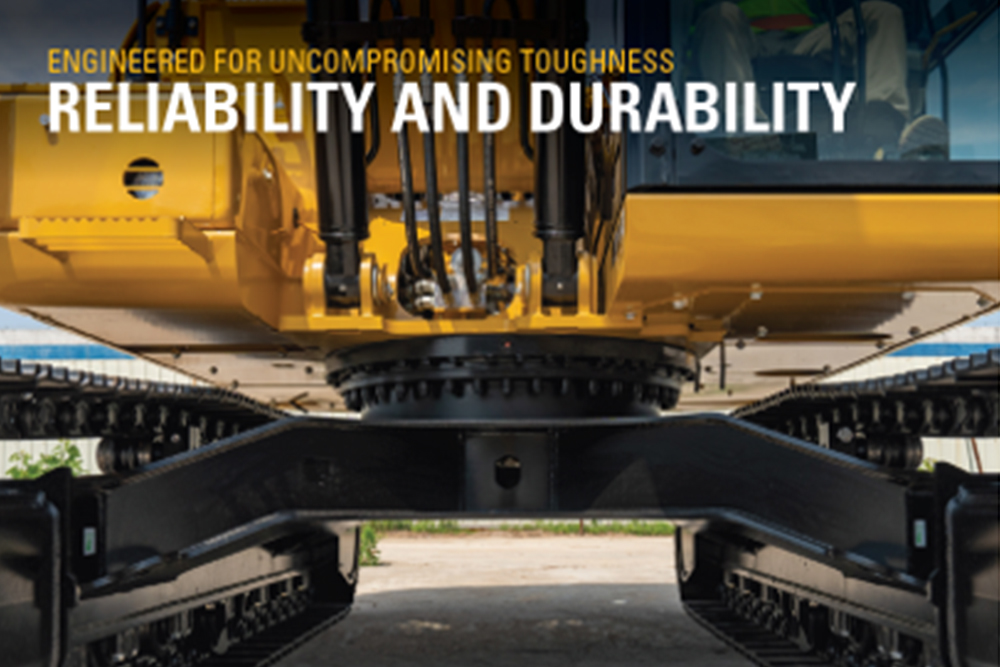

Undercarriage rollers are rebuildable and saaled to prevent dit and debris fram couning internal wear. Gruase lubricanud Inko minimize internal bushing weet, reducing noise and increasing life up to 25. Two robust undercarriage options providing optimized statybosed on bucket selection.

We designed the heavy-duty stick and boom structures using high sta fabricated into a large box section using internal baffles to absorb torsional stress for longer life in quarry applications.

The X-shaped, bos-section carbody provides sscallart resistance to torsional bunding, dissipating struns throughout the base of the machine.

INCREASE EFFICIENCY WITH AN

The 316 GC's hydraulic filtars have increased service life. The hydraulic pilot filter has been oliminated, and the case drain filter has been replaced by a magnet and mash.

The swing drive is now integrated with the hydraulic system, sliminating the need to check or refill a separate oil system.

The refill capacities for most fluids have been reduced with no change in performance or service life.

Almost all daily maintanance can be performed from ground level. Plus, nearly all major mechanical components are accessed from the ground or the service platform, and an automatic tensioner ensures you will never need to make belt adjustments.

Remotely monitor maintenance alerts, hours, and machine location, viewing the data anytime, anywhere with the online VisionLink" system. Use Cat technology to make informed decisions that will simplify maintenance, boost productivity, lower costs, and improve safaty and secunty on your jobsite.

INCREASE YOUR PRODUCTIVITY AND PROFIT

You can easily expand the performance of your 316 GC by utilizing a variety of Cat attachments. Each Cat attachment is designed to fit the weight and horsepower of the Cat excavator for improved performance, safety, and stability.

Protect your hammer from overworking. Auto hammer stop warns you after 15 seconds of C continuous firing and then automatically shuts it off after 30 seconds - all to prevent wear and tear on the attachment and excavator.

| Net Power - ISO 9249 | 114 HP |

| Engine Model | ALUW06DTI |

| Engine Power - ISO 14396 | 134 HP |

| Bore | 4 in |

| Stroke | 4 in |

| Displacement | 351 in³ |

| Main System - Maximum Flow | 400 l/min (106 gal/min) |

| Maximum Pressure - Equipment | 5075 psi |

| Maximum Pressure - Travel | 5075 psi |

| Maximum Pressure - Swing | 3625 psi |

| Swing Speed | 10 r/min |

| Maximum Swing Torque | 45581 ft·lbf |

| Operating Weight | 43600 lb |

| Fuel Tank Capacity | 92.5 gal (US) |

| Cooling System | 5 gal (US) |

| Engine Oil | 4.8 gal (US) |

| Swing Drive - Each | 1.6 gal (US) |

| Final Drive - Each | 1.3 gal (US) |

| Hydraulic System - Including Tank | 60.8 gal (US) |

| Hydraulic Tank | 29.1 gal (US) |

| Boom | Reach 5.7 m (18'8") |

| Stick | Reach 2.25 m (7'5") |

| Bucket | GD .92 m³ (1.20 yd³) GD .92 m³ (1.20 yd³) |

| Shipping Height - Top of Cab | 10.4 ft |

| Handrail Height | 9.7 ft |

| Shipping Length | 31.3 ft |

| Tail Swing Radius | 9 ft |

| Counterweight Clearance | 1.6 ft |

| Ground Clearance | 1.6 ft |

| Track Length | 13.5 ft |

| Length to Center of Rollers | 10.9 ft 3270 mm |

| Track Gauge | 7.3 ft |

| Transport Width | 9.2 ft |

| Maximum Digging Depth | 19.7 ft |

| Boom | Reach 5.7 m (18'8") |

| Stick | Reach 2.5 m (8'2") |

| Bucket | GD .92 m³ (1.20 yd³) |

| Maximum Reach at Ground Level | 30 ft |

| Maximum Cutting Height | 29.11 ft |

| Maximum Loading Height | 20.6 ft |

| Minimum Loading Height | 9.7 ft |

| Maximum Depth Cut for 2440 mm (8 ft) Level Bottom | 18.6 ft |

| Maximum Vertical Wall Digging Depth | 17.7 ft |

| Bucket Digging Force - ISO | 30120 lbf |

| Stick Digging Force - ISO | 25180 lbf |

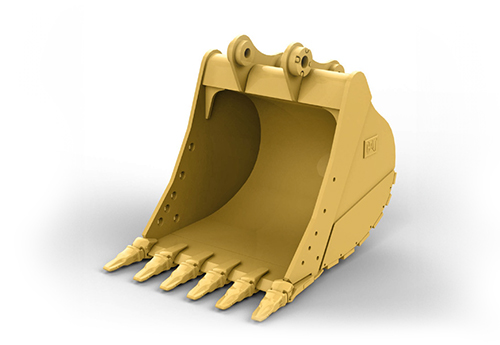

Cat buckets and Cat Ground Engaging Tools (GET) are designed and matched to the machine to ensure optimal performance and fuel efficiency.

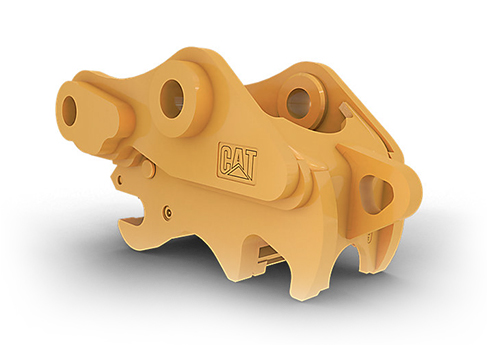

Center-Lock is a pin grabber coupler and features a patent-pending locking system. A highly visible secondary lock clearly shows the operator when the coupler is engaged or disengaged from the bucket or work tool..

Cat® Hammers make short work of your demolition, construction, and quarry needs. Combine the simple, lightweight design of the GC Hammer series with the reliability, durability, and value you expect from Cat products. The result is a low cost per hour solution providing the consistent power and performance you need.

Constructed from high-strength steels and built to last, Cat rippers endure in the toughest conditions. The box-section structure is reinforced for maximum rigidity, transmitting the full machine power to the material being ripped. Rippers feature a replaceable wear tip, and most models also come equipped with a replaceable shank protector.

Cat grapples make Cat excavators the ideal machine for handling loose material, sorting trash, and demolition site cleanup. An array of styles and sizes is available to match excavators to the task at hand.

Multi-processors do the work of many types of demolition tools by use of interchangeable jaw sets. Changing jaws allows a single unit to crush, pulverize, and perform a variety of specialized tasks such as cutting steel rebar and tanks.

Cat shears are designed to take full advantage of the hydraulic flows and pressures produced by Cat excavators – all to enhance productivity without compromising safety or causing premature wear of the shear or carrier.

Mechanical pulverizers are cost-effective tools for recycling demolished concrete debris. The bucket cylinder on the excavator powers the pulverizer, eliminating the need for a dedicated cylinder, associated hydraulics, and additional installation cost.

Cat compactors make job site compaction quick, efficient, and cost effective.

The hydraulic concrete crusher is well suited for demolition in residential areas. The tool combines several demolition operations in one piece of equipment: